Binding

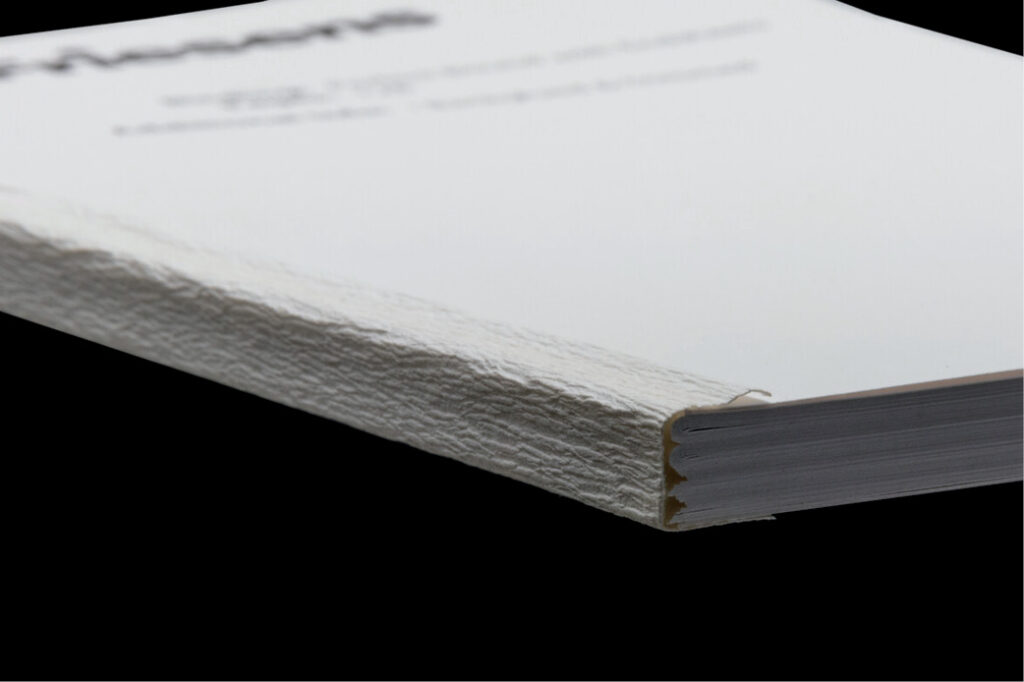

Perfect Binding

Also called adhesive binding. Perfect binding requires no staples or thread and uses hot or cold glue. Hot melt is more common because it is economical and dries quickly. Cold glue is an involved process but has the advantage of allowing the book to open more easily and lie flat.

Layflat Perfect Bound

The book block is perfect bound using glue. The cover is bound to the book block with no glue down the spine to allow the book to lay flat when opened.

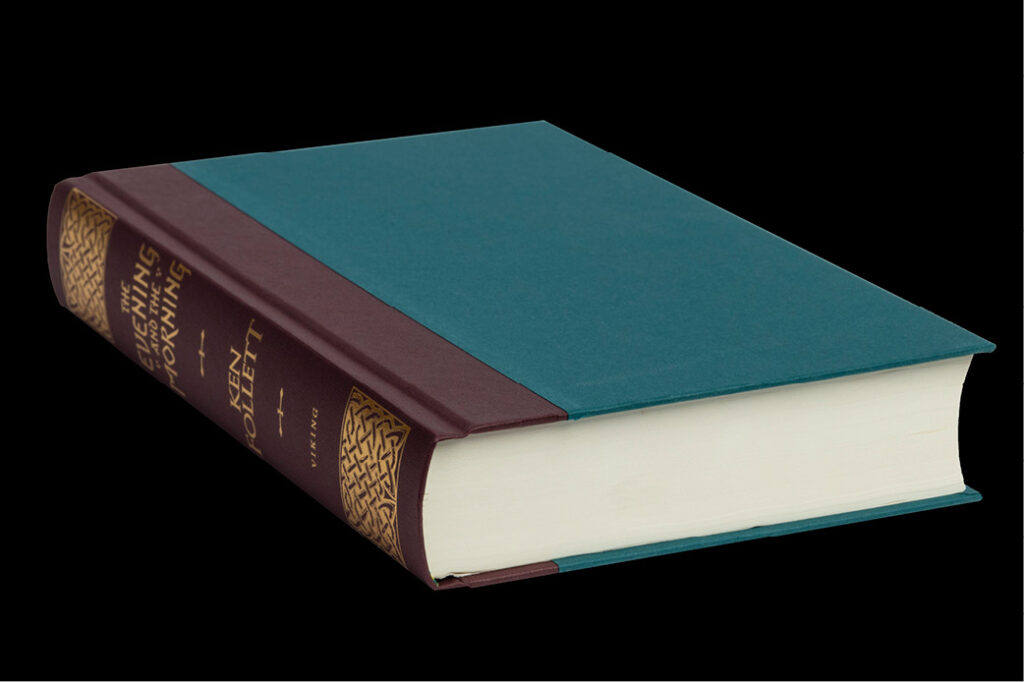

Quarter Binding

Limited edition books often feature quarter binding, historically employing genuine leather on the spine and linen on the front and back. This method is favored for its economic use of leather and the potential for aesthetically pleasing color combinations with complementary materials. Both genuine and simulated leather offer diverse colors and grains, allowing for attractive stock combinations in limited edition book designs.

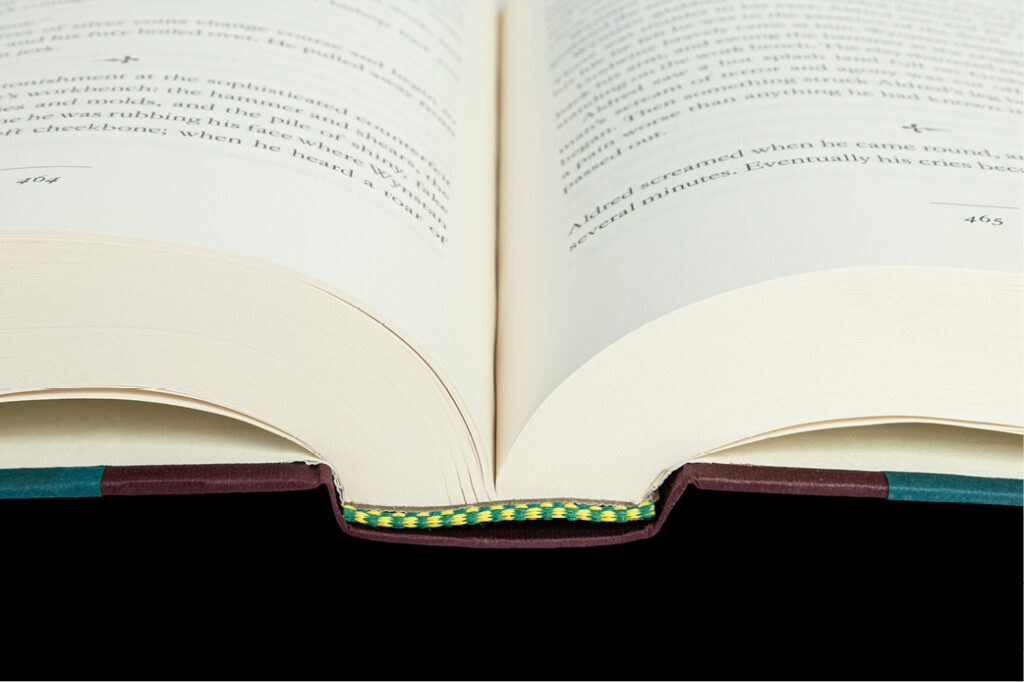

Sewn Binding

Sews signatures using threads. Signatures are sewn together, and an endsheet is put on the front and back. The book block is then attached to the cover. This is common for all hard cover and some softcover books. Commonly referred to as Smyth sewn.

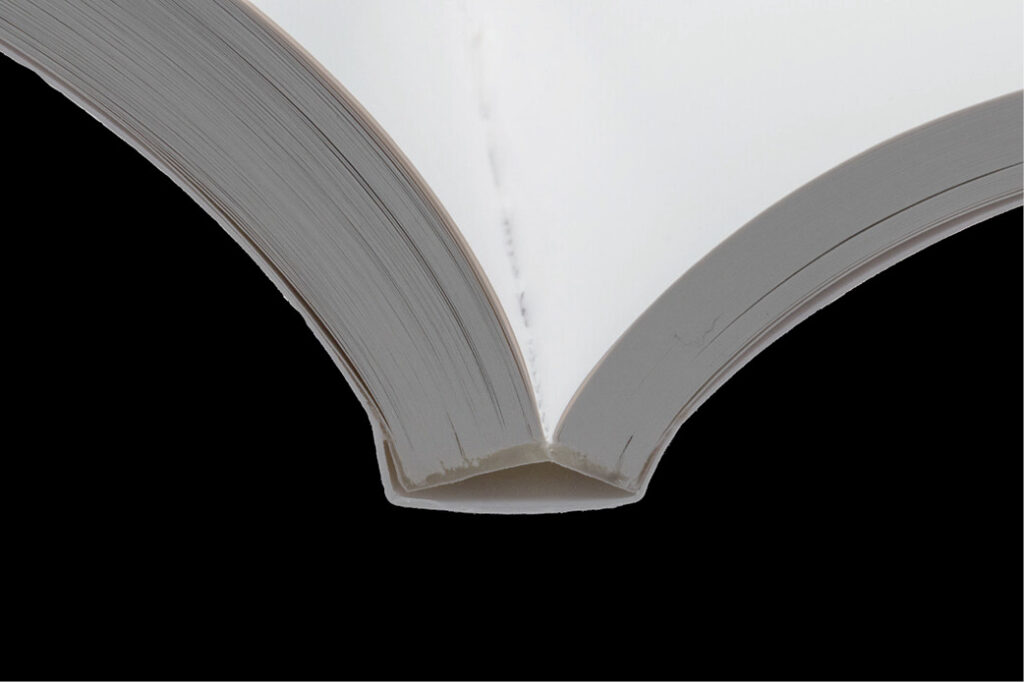

Layflat Sewn

Sews the signatures using threads. The cover is bound to the book block with no glue down the spine allowing the book to lay flat when opened.

Saddle Stitch

A binding process using wire staples most often used in magazines or magazine-type work or books under 96 pages.

Plastic Spiral

A plastic coil run through the pages to allow the book to lay flat when open.

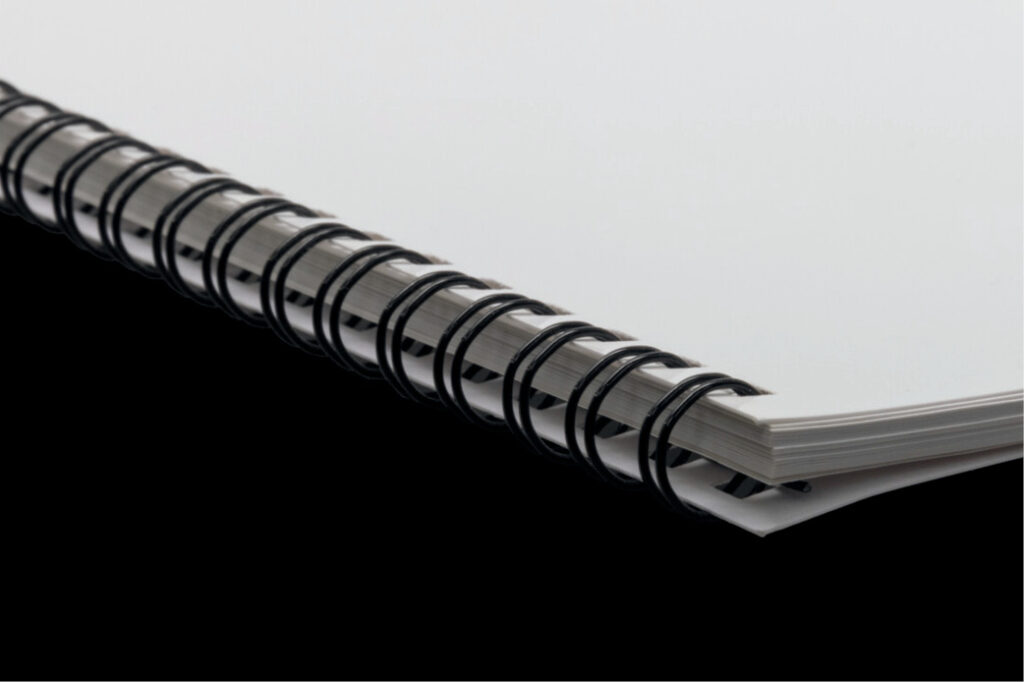

Wiro

A more durable binding than Cerlox for lay flat books. Silver Wire-O is standard and most widely used. However, there are a variety of colours to choose from.

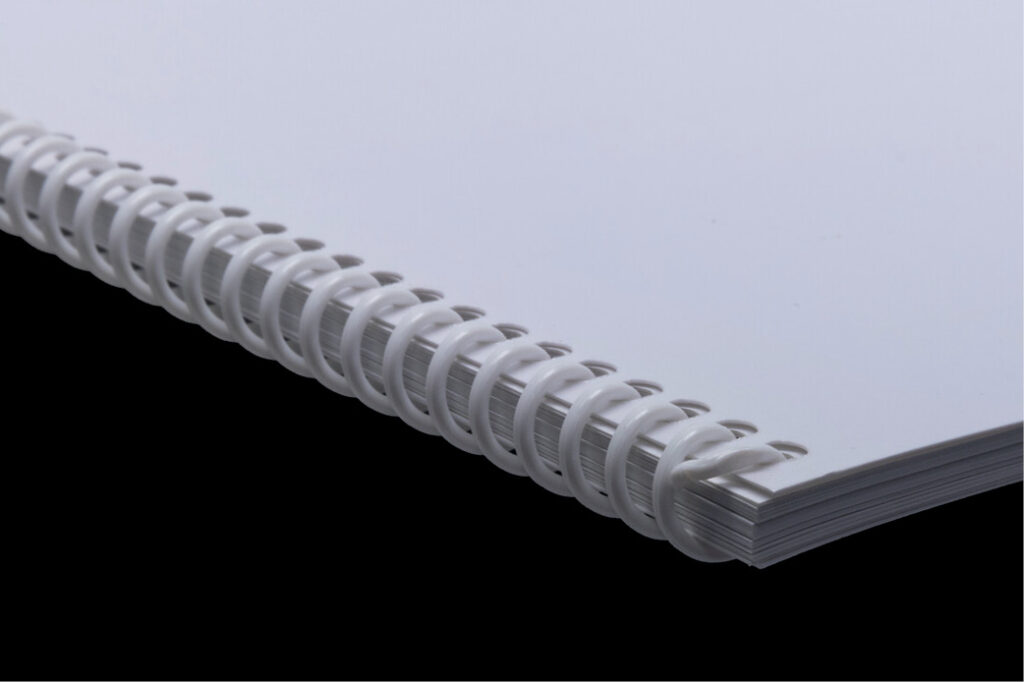

Concealed Wiro

Concealed wiro binding hides the wire spine within the book, providing a clean and professional appearance while ensuring durability and functionality.

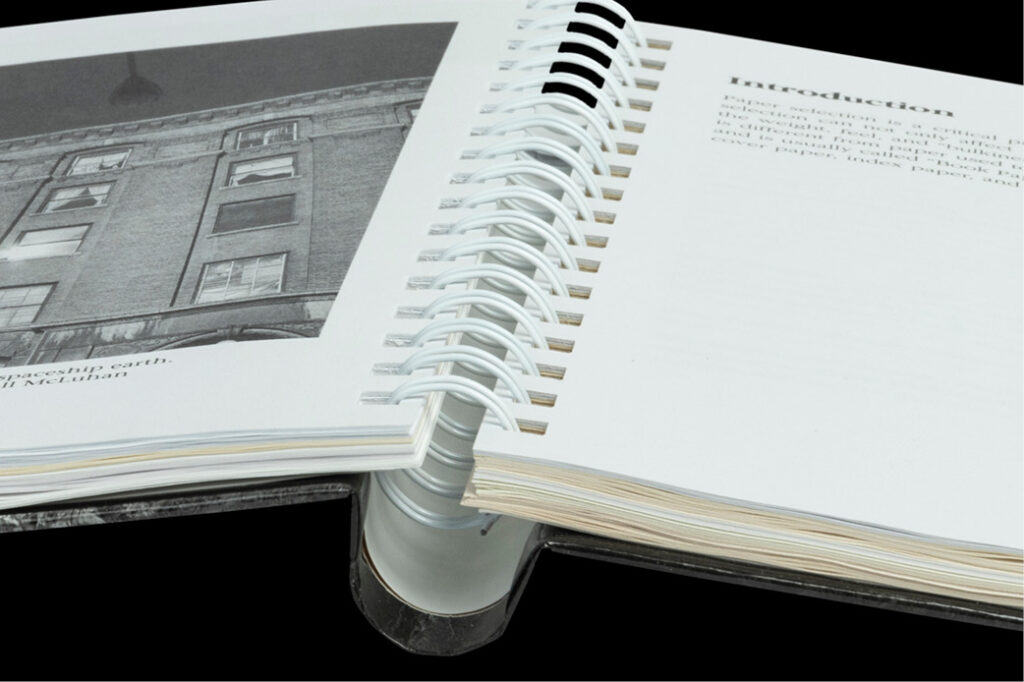

Semi-Concealed Wiro

Semi-concealed wiro binding discreetly holds pages while allowing them to lie flat, offering a sleek finish to your book.

Exposed Binding

Exposed binding typically integrates decorative thread during the sewing process. While glue is used to enhance strength, the cover remains unattached to the spine, allowing the threads and spine to be easily visible, resulting in a distinct and unique finish.