Friesens commitment to the environment is built around making the best use of all our resources and minimizing our ecological footprint. We use our resources as carefully as possible – reusing and recycling whatever we can. Any waste that leaves our plant is recycled in such a manner that it can be used again.

At Friesens, it is our intention to protect our employees, customers, community, and natural environment in order to help sustain global human development. We do this by taking steps to prevent or lessen any adverse impact that might result from our operations and products. We regularly evaluate compliance with all environmental law and regulations and introduce best practice standards throughout our firm. We have long been a steward to our environment, and we will continue to be a leader in environmental stewardship.

Friesens has established a detailed Ancient and Endangered Forest Purchasing Policy. This policy helps provide clear guidelines and implementation measures to fulfill our commitment to being a leader in our industry. As part of Friesens Corporation support of Canopy’s ForestMapper map of global Ancient and Endangered Forests, we support the creation of a science-based conservation planning process, and advocate for the establishment of moratoria in priority ecosystems including, but not limited to, rare ecosystem types and endangered species habitat. For more information please see: Quick Guide to Ancient and Endangered Forests, Why Ancient & Endangered Forests are Irreplaceable, How to Work with Forest Mapper

We have also established an extensive Eco-Friendly Paper Stocking Program to promote and encourage the use of eco-friendly papers.

Download our Legacy of Green Brochure

Did You Know?

Paper facts

- We use approximately 13,000 tons of paper a year

- Approximately 90% of that paper is FSC® certified

- Coated paper – 100% of what we use is FSC® certified

- Uncoated paper – roughly 80% of the paper we use is FSC® certified

- 100% of the paper from the press room, bindery, prepress, and our offices is baled and recycled. That translates into about 120 truckloads of recycled material leaving our plant every year.

- Friesens developed an eco-calculator for customers to use so they can see the trees, water, and energy saved when using recycled paper

Pressroom facts

- We use vegetable-based inks

- We use alcohol-free blanket wash

- We minimize waste by using reusable rags

- We use reusable skids

- We receive our ink in reusable barrels

- We recycle 267,000 lbs of aluminum plates annually

Other facts

- Hydroelectric power and wind farms provide energy for our plants

- We created a waste management system that helps us successfully track our waste and minimize it for the production of your books

- We eliminated the use of Styrofoam cups and trays in our lunchrooms

- We participate in our local community recycling program so staff can minimize any garbage going to our landfill

Canopy

Ancient Forest Friendly™ (AFF): Friesens offers Ancient Forest Friendly™ paper, which helps to reduce our carbon footprint and protect ancient and endangered forests and ecosystems. The Ancient Forest Friendly™ logo represents the highest ecological qualities in the paper industry. If you use paper designated as Ancient Forest Friendly™ contact your Friesens representative and ask about using the AFF logo on your book.

We are conscious of the impacts of fibre sourcing decisions on endangered species, high conservation value forests, communities and climate, in places like the Boreal, Coastal Temperate rainforests and Indonesian rainforests. Friesens is working closely with not-for-profit Canopy on policy implementation to ensure we carefully assess our fibre sourcing to avoid ancient and endangered forest regions.

Second Harvest: Friesens is committed to the conservation of the world’s ancient and endangered forest ecosystems. As part of that commitment, we strongly support the North American commercial scale development of pulp, paper and packaging alternatives that are derived from agricultural residues like wheat straw as a way to diversify the fibre basket and meet our continued need for high-quality, cost-effective products.

Pack4Good Position Statement: Friesens recognizes that single use packaging, whether plastics or paper, currently exerts an impact on ecosystems at the resource extraction point, during production and in disposal. Addressing this requires a wholistic approach that doesn’t increase pressure on one globally vital ecosystem (e.g. forests) in order to reduce the pressure on another (e.g oceans). It is both imperative and possible to create changes in packaging use, sourcing, production and end-of-product-use management to support the shift away from single-use plastics and enable conservation of ancient and endangered forests concurrently.

Therefore, we, as a supporting partner of Canopy’s Pack4Good Initiative, commit to:

- Ensure the paper-based packaging we use does not include fibre sourced from Ancient and Endangered Forests[i] by end of year 2022.

- Prioritize innovative packaging design to reduce overall material needs.

- Give preference to paper-based packaging with high-recycled content, specifically post-consumer waste content.

- Encourage our suppliers that are found to be sourcing from Ancient and Endangered forests to change practices and/or re-evaluate our relationship with them.

- Work with innovative companies and Canopy to continuously expand the availability and development of next generation solutions with a focus on agricultural residues[ii] and post-consumer recycled content.

- Source forest fibre from forests certified under the Forest Stewardship Council®(FSC) system, including any plantation fibre, when recycled fibre and agricultural residue fibre is unattainable.

- Request that our suppliers recognize, respect and uphold human rights and acknowledge the right of Indigenous People and rural communities to give or withhold their Free, Prior and Informed Consent (FPIC).

- Support conservation solutions and seek opportunities to inform the public on these issues and solutions through our marketing and communications.

- Adopt specific targets and timelines by the end of 2020 to track and report on our progress.

[i] https://canopyplanet.org/tools/forestmapper/

[ii] https://canopyplanet.org/campaigns/next-generation-solutions/

Please visit www.canopyplanet for more information.

Forest Stewardship Council®

The Forest Stewardship Council® (FSC®) is an international certification and labeling system for products that come from responsibly managed forests and other responsible sources.

When you buy products with the FSC® logo, you’re guaranteed your purchase supports healthy forests and strong communities. For all, forever.

Please visit www.fsc.org for more information.

Eco Labeling

Friesens offers three types of environmental labeling:

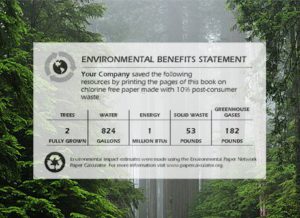

Eco Audit Label

Shows environmental resources saved by using post-consumer wastepaper. Based on calculations by the Environmental Paper Network

Forest Stewardship Council® (FSC) Label

Promotes forests that have been certified, and the wood fibre in the paper has been tracked from a certified forest to the end user, protecting ancient forests.

Ancient Forest Friendly™ (AFF) Label

The Ancient Forest Friendly™ logo certifies that the pulp used to make this paper is sourced from regions that do not contain any Ancient Forests. Ancient and endangered forests are defined as intact forest landscape mosaics, naturally rare forest types, forest types that have been made rare due to human activity, and/or other forests that are ecologically critical for the protection of biological diversity.